PDR (Paintless Dent Repair) offers an eco-friendly solution for auto repairs, prioritizing sustainability by minimizing environmental impact and resource consumption. It preserves vehicle paint jobs, reduces waste, lowers energy use, and diminishes carbon footprint, aligning with industry's pursuit of environmental responsibility while ensuring long-lasting results and maintaining aesthetic appeal.

In today’s eco-conscious world, choosing sustainable repair options is no longer just a trend but a necessity. Poly Methacrylate (PMA) Damage Repair (PDR) offers an innovative and environmentally friendly solution for vehicle damage restoration. This article delves into the green auto repair approach of PDR, highlighting its advantages in environmental conservation and recycling. By understanding PDR benefits, we can contribute to a greener future while keeping our roads safe and vehicles looking their best.

- Understanding PDR: A Green Auto Repair Approach

- Advantages of PDR for Environmental Conservation

- PDR Techniques and Their Positive Impact on Recycling

Understanding PDR: A Green Auto Repair Approach

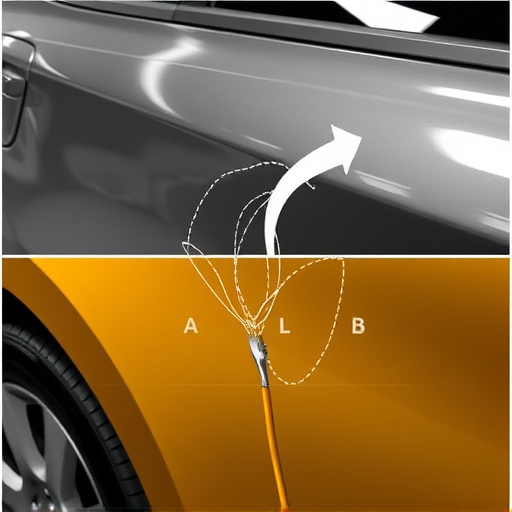

Polished Restoration (PDR) is a green auto repair approach that focuses on minimizing waste and maximizing efficiency in car dent removal and automotive body work. Unlike traditional paint repair methods, PDR specialists use specialized tools to gently reshape and restore damaged areas of a vehicle’s exterior, without affecting the surrounding paint or material. This eco-friendly process reduces the need for costly replacement parts and minimizes exposure to harmful chemicals commonly used in conventional car paint repair.

By leveraging PDR benefits, such as reduced environmental impact, lower resource consumption, and decreased carbon footprint, auto owners can contribute to a more sustainable future while keeping their vehicles looking like new. Whether it’s a minor dent or significant damage, PDR offers an effective solution that preserves the vehicle’s original finish, enhances aesthetics, and ensures long-lasting results, making it a preferred choice for those seeking environmentally conscious automotive body work.

Advantages of PDR for Environmental Conservation

The environmental impact of auto repairs is a growing concern, but Professional Dent Repair (PDR) offers a sustainable solution with numerous advantages for ecological conservation. Unlike traditional automotive body work that often involves extensive painting and material replacement, PDR focuses on minimizing waste and preserving the original vehicle surface. By repairing dents and dings instead of replacing entire panels, auto repair shops can reduce the demand for new materials, lowering energy consumption and greenhouse gas emissions associated with manufacturing processes.

This eco-friendly approach also extends to tire services, as PDR techniques can restore damaged tires to their original condition, prolonging their lifespan and decreasing the need for frequent replacements. As a result, auto repair shops that specialize in PDR contribute to a circular economy by giving tires and vehicle panels a second life. Moreover, the reduction in waste and material usage translates into less pollution, making PDR benefits both environmentally and economically sound choices for consumers and auto repair industries alike.

PDR Techniques and Their Positive Impact on Recycling

PDR (Paintless Dent Repair) techniques have revolutionized eco-friendly repair options, offering a sustainable approach to vehicle bodywork. This non-invasive method involves skilled technicians using specialized tools to gently remove dents and dings from a vehicle’s surface without damaging the paint or requiring additional paint applications. By preserving the original factory finish, PDR minimizes waste generation, as there is no need for discarding and replacing paint or repainting the entire vehicle.

The positive impact of PDR on recycling is significant. In a typical collision damage repair scenario, vehicles often require substantial amounts of materials to restore them to their pre-accident condition. Traditional methods may involve stripping the paint, using hazardous chemicals for degreasing, and discarding large amounts of waste. However, PDR significantly reduces this environmental footprint by keeping the original paint intact, minimizing material waste, and cutting down on energy consumption associated with repainting processes. This makes vehicle body shops more eco-conscious, aligning with the growing demand for sustainable practices in the automotive industry.

By adopting PDR (Paintless Dent Repair) techniques, the auto repair industry is not only offering efficient solutions for dented vehicles but also contributing significantly to environmental conservation. The eco-friendly nature of PDR, with its minimal use of resources and zero paint waste, makes it a beneficial choice for both car owners and the planet. PDR benefits extend beyond surface repairs, promoting a more sustainable future for the automotive sector.