Paintless Dent Repair (PDR) offers significant environmental advantages over conventional paint methods, including lower emissions, reduced energy consumption, and decreased VOC demand. By minimizing paint removal and waste, PDR is an eco-friendly choice for repairing minor car damage like dents, dings, and scratches, appealing to sustainability-conscious consumers. Moreover, PDR reduces the carbon footprint of vehicle ownership by conserving resources and avoiding hazardous chemicals typically used in traditional auto body shop operations. This innovative technology also provides economic benefits such as quicker repairs, reduced wait times, and competitive pricing, fostering stronger client relationships in busy shops.

In today’s eco-conscious world, choosing sustainable car repair options is more important than ever. Paintless dent repair (PDR) offers an environmentally friendly solution with numerous advantages. This non-invasive technique preserves vehicle aesthetics and reduces waste by eliminating the need for paint and additional materials. Discover how PDR benefits are revolutionizing the automotive industry, promoting both environmental sustainability and cost-effectiveness.

- Understanding PDR: The Eco-Friendly Approach to Car Repairs

- Advantages of PDR for Environmental Sustainability

- How PDR Benefits Are Transforming the Automotive Industry

Understanding PDR: The Eco-Friendly Approach to Car Repairs

Painting less isn’t just a buzzword; it’s a proven eco-friendly approach to car repairs known as PDR (Paintless Dent Repair). This method revolutionizes how we fix minor car damage, from dents and dings to scratches, by restoring the vehicle’s original finish without the need for traditional painting. By minimizing the use of materials and energy-intensive processes, PDR offers significant environmental benefits.

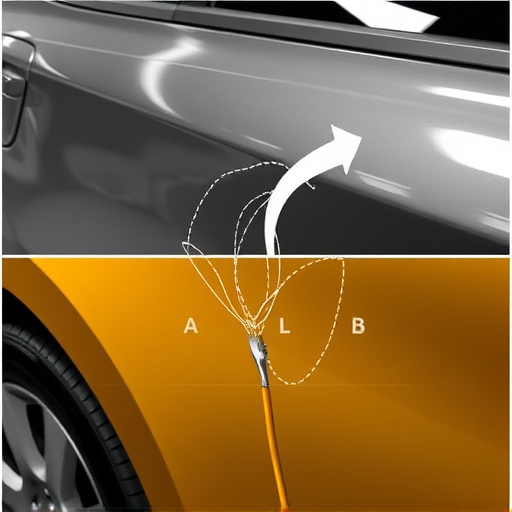

PDR technicians expertly manipulate specialized tools to gently remove dents, ensuring minimal or no paint removal. This not only reduces waste but also cuts down on the carbon footprint associated with repainting. When compared to conventional auto body repair and auto glass repair methods, PDR benefits include lower emissions, less energy consumption, and decreased demand for volatile organic compounds (VOCs), making it a preferable choice for those concerned about sustainability.

Advantages of PDR for Environmental Sustainability

The benefits of Plastic Degradation Repair (PDR) extend far beyond mere aesthetic improvements to a vehicle. One of its most significant advantages is its environmental sustainability. PDR techniques allow for the repair of dents and dings without the need for traditional paint jobs, which often require substantial amounts of energy-intensive manufacturing processes and hazardous chemicals. By minimizing the amount of new paint needed, PDR reduces waste and lowers emissions associated with vehicle body shop operations.

This eco-friendly approach is particularly beneficial for vehicle bodywork maintenance. Unlike a complete vehicle paint repair, which can generate significant waste and pollution, PDR revitalizes the existing paint and plastic surfaces. This not only conserves resources but also helps to reduce the carbon footprint of vehicle ownership, making it a preferred choice for environmentally conscious consumers looking for efficient solutions in their local vehicle bodywork services.

How PDR Benefits Are Transforming the Automotive Industry

The automotive industry is experiencing a quiet revolution thanks to PDR (Paintless Dent Repair) benefits. This innovative technique is transforming how we approach auto bodywork and vehicle paint repair, offering both environmental and economic advantages. By eliminating the need for traditional vehicle paint repair methods that often involve toxic chemicals and significant waste, PDR contributes to a greener automotive landscape. This eco-friendly approach not only reduces the carbon footprint of auto collision repair shops but also minimizes the impact on local environments.

PDR benefits extend beyond sustainability, enhancing overall efficiency in the industry. The non-invasive nature of PDR allows for quicker and more cost-effective repairs compared to conventional methods. This efficiency gains are particularly noticeable in busy auto shops where time and resources are valuable. By adopting PDR, these facilities can better manage their workloads, reduce customer wait times, and offer competitive pricing, fostering a stronger relationship with their clientele.

PDR benefits have not only revolutionized the automotive industry but also contributed significantly to environmental sustainability. By prioritizing eco-friendly repair options, PDR reduces waste, conserves resources, and minimizes the carbon footprint associated with traditional car repairs. As awareness of these advantages grows, we can expect a greener future for the automotive sector, where PDR plays a pivotal role in shaping a more sustainable landscape.